- Estate Pipe

- Sold

|

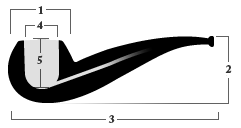

1.OUTSIDE DIAMETER: 38 mm - 1.50 in

2.BOWL HEIGHT: 46 mm - 1.81 in 3.LENGTH: 146 mm - 5.75 in 4.CHAMBER DIAMETER: 22 mm - 0.87 in 5.CHAMBER DEPTH: 38 mm - 1.50 in WEIGHT: 42 gr - 1.48 oz |

Briar pipe handmade by Dunhill. Classic design, perfect architecture. Over 100 years of tradition and quality in your hands.

0

Dunhill - Root Briar 1R

"The challenge of a Dunhill history is to separate myth and legend from the history. This however, may be impossible. The story of Alfred Dunhill is so tied up with myth that the myths are now part of the history. Alfred Dunhill, being aware of this phenomenon, probably perpetuated many of such myths. Nonetheless, let us try and begin at the beginning in the early 1900’s.

Alfred Dunhill inherited a harness business in 1893 at the age of 21. Alfred soon saw that the age of the automobile was coming and decided to convert his father’s factory from horse-drawn carriage accessories to motor accessories. “Dunhill Motorities” was soon born and Alfred was fast at work inventing and creating all possible accessories. In 1904 Alfred invented the “Windshield Pipe,” hoping to combat some of the difficulties a smoker would face while driving. It was this sort of innovation in response to the customer’s needs that would make Dunhill Pipes the leader in its field.

In 1906, the first pipes and tobacco shop opened on Duke St. The shop soon came to be known for its customized blends. Each customer could come and create his own recipe, noted in a little book entitled “my mixture.” This is a prime example of Dunhill’s ability to tailor itself to the customer’s needs. Alfred Dunhill however, was unsatisfied with the current quality of available pipes. The pipes coming in from France were highly varnished and consequently clogged the pores of the briar. They were simply not doing justice to his creative blending.

Alfred opened a small factory of his own in 1910. He set down two principles that would guide the production of Dunhill Pipes. First, pipes would be made of only the finest quality briar, with exacting care by expert craftsmen. Secondly, the pipes would be priced accordingly; the customer would recognize the value of a superior product. This ran counter to the current trend of inexpensive pipes of poor quality that one simply discarded after a short while.

The Dunhill pipe was made to last a lifetime and always with an eye to utility. It must smoke well and continue to do so with age. To this end, Alfred invented the aluminum ‘inner tube’ to keep the innards of the pipe clean. When the pipe became dirty the tube could simply and easily be replaced. Note, of course, that this innovation predated the widespread use of pipe cleaners.

In 1915, the famous white spot was introduced for very practical concerns. With straight pipes, customers had trouble knowing which way to insert the handmade vulcanite mouthpieces. So Alfred Dunhill ordered white spots to be placed on the upper side of the stem. This very practical solution would become a definitive trademark of Dunhill pipes. The “white spot” soon became known as a symbol of quality.

Alfred Dunhill wanted his pipes to be known around the world. WWI provided him the perfect opportunity to promote his product on an international scale. When an order was placed by an officer serving in Northern France, Alfred would send additional pipes with a note asking that they be distributed among his fellow officers. The pipes were sold not only to British officers but to Americans, French, Belgians and Canadians. By the end of the war the Dunhill Pipe, with its “white spot”, was known the world over.

Alfred Dunhill’s most revolutionary innovation was the Shell pipe in 1917. How this technique of sandblasting came about is somewhat of a mystery. The story often told is that Alfred Dunhill went down into his basement in the wintertime to make a couple pipes and accidentally left one, a half finished piece, by the heating boiler. He returned sometime next summer, having suddenly thought of the pipe, only to find some of the grain had ‘shrunk’, leaving a relief pattern. Obviously, this is apocryphal, probably resulting from the ‘shrunken’ look that sandblasts (especially the gnarly ones of that era) frequently have. Some say the name “Shell” came from the shriveled look the pipe took on after the sandblasting process. Alfred realized Algerian briar, then considered inferior, could be used in this new process. The softer wood could be ‘blasted away’, leaving behind only the harder briar and the beautiful natural pattern of the wood. Originally, the Shell pipes were not stamped because the sandblasting technique, not yet being refined, made recognizing the standard shape much more difficult. Though the Shell finish certainly did not arise from accidentally forgotten pipes in the cellar, it was definitely an important innovation on Dunhill’s part.

Another new technique ended up ensuring the quality of Dunhill pipes. Before the sandblasting process, Dunhill would have the Algerian briarwood bowls immersed in olive oil for several weeks. Afterwards, they were left to dry, with the excess oil being occasionally wiped off. This method was originally developed for aesthetic reasons, but it turned out that the oil caused impurities to be forced out of the wood, resulting in a faster curing process. A further consequence of this process was the briar became incredibly durable, making the occurrence of burnouts much less frequent.

Alfred Dunhill went on to open international stores in NYC in 1921 and a store in Paris followed shortly afterwards. The 1920’s and 30’s were successful years for Dunhill. By 1924, 260,000 pipes were sold a year through the Dunhill shop on Duke St. Just two decades old, Dunhill Limited was becoming famous for supplying the most elite clientele in the world. Dunhill developed ties with the royalty, supplying George VI with tobacco through the thirties. Later during WWII, the company kept Winston Churchill constantly supplied with the cigars that would become such an essential part of the famous British icon.

The company expanded, offering specially designed pipes during the 1920’s that would be marked OD for ‘own design.’ This concern for marking and always having patent numbers on pipes is what allows for much of the dating process today. The stamping during the twenties was inconsistent and some of the early shell pieces lack marking altogether. In the 1930’s there was the desire to standardize. A shape chart was developed that used numbers and letters to signify a specific shape. Each new pipe would be stamped to identify its size and shape.

World War II presented some problems for Dunhill. The Dunhill shop on Jermyn St. was destroyed during the Blitz and had to be relocated. The supply of briar became more tenuous. Italian briar was restricted by the Italian government to be used only by Italian carvers. The Algerian briar became more difficult to acquire. The war also left Europe in a shambles. Depressed financially, there was no place in Europe for high-end luxury goods. Consequently the American market grew and American taste determined the direction of Dunhill pipe making. Large pipes and traditional shapes were in demand and so Dunhill created a new line of pipes called the “800” OD series, recycling the old OD stamp....

....Dunhill has always been creative in its designs and finishes. It is however, Dunhill’s principle of absolute quality achieved through unrelenting quality control that has set Dunhill apart from the rest. Dunhill pipes regardless of shape, size, and finish must always smoke well. This principle laid down in the early days of the company continues today. At the Dunhill factory, just outside of London, pipes are made by 15 full-time expert craftsmen who boast a cumulative work experience of 260 years. Knowing a high quality product must begin with the best possible material, the briar used by Dunhill is from carefully selected burls from bushes a hundred years old. Even with selecting only the highest quality briar with the finest grain, once the briar bowls begin to be carved certain flaws are exposed and many bowls have to be discarded. At every stage of the process there are a mandatory quality checks that ensure a Dunhill pipe will smoke well from the first to last bowl of tobacco, regardless of age. Each step in the six-week process is done by hand. Over 90 different steps are required in a process that has changed very little since the days of Alfred Dunhill almost a century ago.

Dunhill Pipes are now prized collector pieces and the most famous pipes in the world. Alfred envisioned the Dunhill Pipe to be something special, a pipe to be coveted for its quality, sophistication and refinement. Alfred Dunhill’s vision continues today. To Smoke a Dunhill is to experience this tradition, a tradition of excellence that is perhaps the greatest in the world of pipes."

Straight grained pipes were formerly graded A through H, but are now graded with one to six stars, with the letters G and H still used for the very finest pieces.

Data sheet